DriZzling can be done in a broad range of machines. The whole trick to become engine grade gas, is the strange fuel feed technique, already in broad expleaned on this blog" wich is called "The DriZzling method". Not the machine is important, but the fuel feed.

There are people converting a classical "Imbert" design. Others adapt a FEMA and some just build a new unit based on the simple sketch posted on the Yahoo woodgas group.

All have a lot in commen, the new ones and the adapted ones. The most specififique charasterics beeing the gasifier complete open top and not needing Nozle's to fix the oxidation, nor suply oxigen.

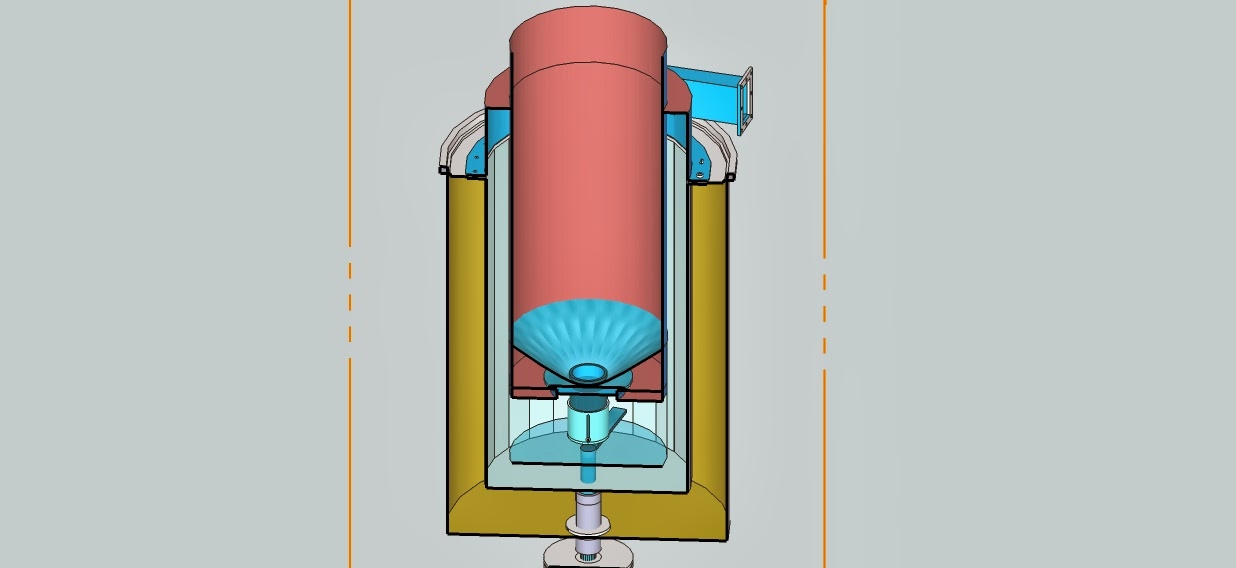

However, as lot's of people asking for drawings and design guides, me and Pascal started talking how an gasifier best suited for "DriZzling" should look like.

We put some design rules up front, such as; the gasifier should be easy to clean. All parts should be fast accesable. The "DriZzleR" should be flexibla and adaptable for differnt fuels. It should be made with ready available of the shelve materials and easy to build or assemble.

Although not yet build the result of this talks let to a first concept, which you find herunder.

Beware. We are also still in the laboratory stage of the developing of the "DriZzleR" and the "DriZzleR Method", changing and learning everyday. Putting the drawing here does not mean that this concept will be build like this, but is is a start. We sure will keep you informed on how this concept gets materialised and how the tests will look like.

Any sugestions more than welcome

Luk Vanhauwaert

Keine Kommentare:

Kommentar veröffentlichen