DriZzling can be done in a broad range of machines. The whole trick to become engine grade gas, is the strange fuel feed technique, already in broad expleaned on this blog" wich is called "The DriZzling method". Not the machine is important, but the fuel feed.

There are people converting a classical "Imbert" design. Others adapt a FEMA and some just build a new unit based on the simple sketch posted on the Yahoo woodgas group.

All have a lot in commen, the new ones and the adapted ones. The most specififique charasterics beeing the gasifier complete open top and not needing Nozle's to fix the oxidation, nor suply oxigen.

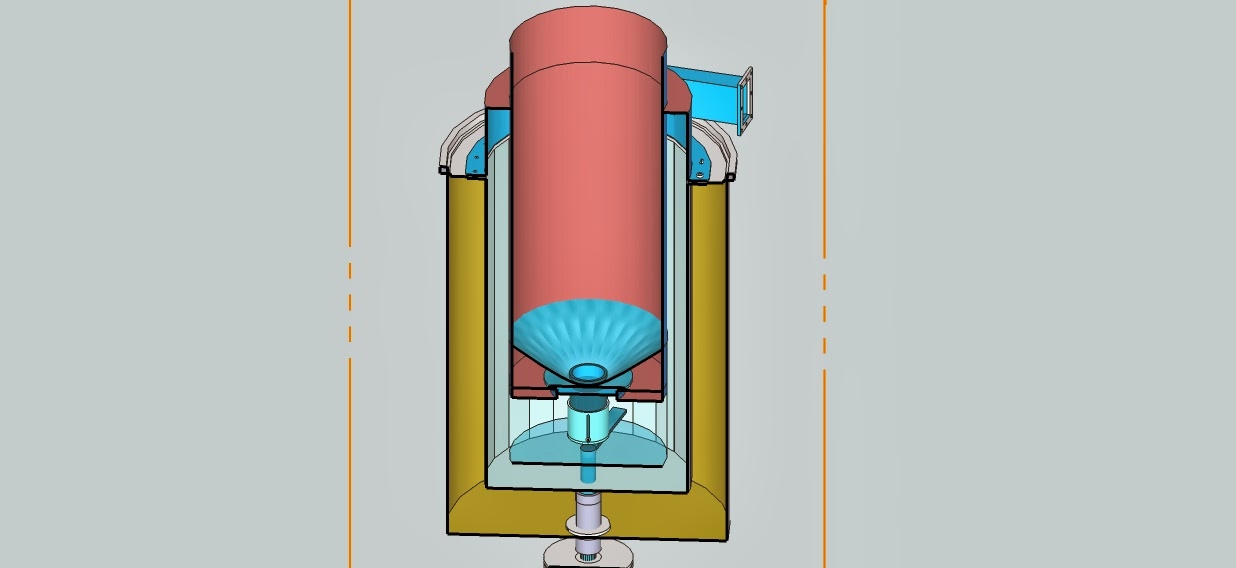

However, as lot's of people asking for drawings and design guides, me and Pascal started talking how an gasifier best suited for "DriZzling" should look like.

We put some design rules up front, such as; the gasifier should be easy to clean. All parts should be fast accesable. The "DriZzleR" should be flexibla and adaptable for differnt fuels. It should be made with ready available of the shelve materials and easy to build or assemble.

Although not yet build the result of this talks let to a first concept, which you find herunder.

Beware. We are also still in the laboratory stage of the developing of the "DriZzleR" and the "DriZzleR Method", changing and learning everyday. Putting the drawing here does not mean that this concept will be build like this, but is is a start. We sure will keep you informed on how this concept gets materialised and how the tests will look like.

Any sugestions more than welcome

Luk Vanhauwaert

10. Februar 2014

9. Februar 2014

Es gibt schon wieder einen DriZzleR Nachbau vom User: spacepeter

den kompletten Artikel finden man auch unter:

Der DriZzleR ist so ziemlich das gutmütigste was ich an Kleinstvergasern gesehen habe.

Der Durchmesser der Brennkammer war 15 cm und das hat schon sehr ordentlich Gas produziert.

Hackgut und Pellets wurden verfeuert.

Ich sehe das der DriZzleR-Vergaser besonders interessant ist für kleine Leistungen wie ein Honda Notstromaggregat da es für solche Leistungen nicht wirklich einen Imbert gibt oder nur sehr schwer zu bauen ist (habs nicht hinbekommen).

Das gleichmäßige Brennstoff einfüllen muss allerdings geübt werden.

Das er gefährlicher sein soll wie ein z.b. ein Imbert konnte ich nicht feststellen.

Ich würde mal das Gegenteil behaupten da ich noch keine einzige Verpuffung feststellen konnte (auch beim Leerbrennen nicht)

Der Durchmesser der Brennkammer war 15 cm und das hat schon sehr ordentlich Gas produziert.

Hackgut und Pellets wurden verfeuert.

Ich sehe das der DriZzleR-Vergaser besonders interessant ist für kleine Leistungen wie ein Honda Notstromaggregat da es für solche Leistungen nicht wirklich einen Imbert gibt oder nur sehr schwer zu bauen ist (habs nicht hinbekommen).

Das gleichmäßige Brennstoff einfüllen muss allerdings geübt werden.

Das er gefährlicher sein soll wie ein z.b. ein Imbert konnte ich nicht feststellen.

Ich würde mal das Gegenteil behaupten da ich noch keine einzige Verpuffung feststellen konnte (auch beim Leerbrennen nicht)

7 Minuten nach dem Start mit Kohle

Zu viel Brennstoff

dauerhaftes Glühen der Reaktorwand aus 5 mm Stahl

Spacepeter

Look at the different flames from DriZzleR.

---

Schaut euch die unterschiedlichen Flammen vom DriZzleR an.

In all three flames you see the quantity of gas consumed the VW needed in the operation.

Here, a vacuum of 70-80 mbar is generated in the system.

---

In allen 3 Flammen sieht man die Gasmenge die der VW im Betrieb benötigt.

Dabei wird ein Unterdruck von 70-80mBar im System erzeugt.

Dabei wird ein Unterdruck von 70-80mBar im System erzeugt.

The first flame was filmed two minutes after lighting. This flame is unfiltered.

---

Die erste Flamme ist 2 Minuten nach dem Anzünden gefilmt worden. Diese Flamme ist ungefiltert.

The second Flame 10 minutes after lighting. This flame is unfiltered just like the first.

---

Die 2. Flamme 10 Minuten nach dem Anzünden. Diese Flamme ist genau wie die erste ungefiltert.

The third Flame has been made 15 minutes after the lighting with the filter is on.

---

Die 3. Flamme ist 15 Minuten nach dem Anzünden mit eingeschaltetem Filter gemacht worden.

We also seen in the unfiltered condition, the flame already beautiful bright blue. It can thus be of very long filter runtimes.

---

Man sieht auch im ungefiltertem Zustand ist die Flamme schon schön kräftig blau. Man kann also von sehr langen Filterlaufzeiten ausgehen.

the DriZzleR Gasifier engine testrun´s

here you can see the 2 generators running on Woodgas powered by the DriZzleR Gasifier.

1. Generator is an VW 1,6l

4 cylinder engine. powering an asynchron generator up to 11kW

running on pellets as fuel

2. Generator is an Honda EX 5500 0,4l

2 cylinder engine powerering an synchron generator up to 5,5kW

running on pellets as fuel

and also running with woodchips as fuel

have fun watching the different setups without changing the gasifier.

Thank you Pascal to give me an opportunity to explain a little further what I experiented with open top systems and what my opinions on them are and how I came to a new open top design and a new gasifieing method. Also to express my gratitude to you as the furst man to realy fully understand the potentials of the new and revolutionary concept in gasifieing. If it was not you who tested this method inyour already fully build cogeneration setup, maybe the "DriZzleR" and the "DriZzleR Method" would had gon unnoticed. Therefor I say "The DriZzleR" is a team. PASCAL and LUK.

Fundamental diference is; that the oxidationzone in a "DriZzleR" gasifier is not able to kreep up, This by the simple fact that in a "DriZzleR" there is no possibility to kreep up. Where the hopper or the fuel tube in a standard gasifier is kept full, (See a sketch of a stratified gasifier). Or where it is filled up by an auger in order “to feed it” and not to “starve it”, in a Drizzler the hopper is almost completely empty. (apart from a few hundreds gramm coal and the regular few hundred gram fuel to prevent it from burning out). The hopper in the DriZzleR is kept systematicaly at the lowest level. (This level can vary from fuelsort to fuelsort). The little bit material (red in the drawing) is part reduction,coalbed and oxidation, all in one. I call it the “Flaming Pyrolysebed”

What I am writing below in this little article is my own opinion based only on what I learned and observed myselve. I am not a scientist and If I am missing the point or telling nonsense then please join in and correct me.

A litle history is at place. When Dr Reed in the eighty’s invented the stratified downdraft , by that, one could say: he is the father of the FEMA. Was the man who wrote the FEMA manual “LaFontaine”, not a coworker with Reed? Anyway somewhere I read that Reed was very euphoric about his invention because it beeing an open top system thus it overcame many of the limits of the closed Imbert design. This specialy in the field of stationary systems.

This euphorism did not lasted long. Open top systems got fast a bad reputation. “Do not even bother building one you will produce nothing but tar”, is a commen reaction on forums that people get when they mention their desire to build one.

Despite that reputation and the negative comments, there are always people that keep trying to develop a workable open top, simply because it’s advantages over the Imbert.

Because of these advantages so many FEMA’s have been build (and search the net), even today this design further atracts many builders.

But as many FEMA builder soon expirienced The FEMA, as practicaly every open top gasifier, has the big problem that it is almost impossible to keep the oxidationzone fixed at a certain level. The oxidation has a tendency to wander upwards to where the oxigen is. With the oxidation kreep-up, the temperature in the coalbed drops and the gasifier gets too cool, and unable to crack all volatiles and tar. Tar condenses further on the road, with all the known problems with it.

Some attemps have been made to stop this kreeping-up of the oxidation, by trying to fix it around a nozle system. As is known from Imbert. Groeneveld did it with his central Nozle and Mukunde with his angled Nozle pointed in the reduction. They both booked more or less succeses. I have also wandered that road in the begining. I tested with A central nozle from above, a central nozle from below....without nozle.

But still, keeping the oxidation fix, remains problematic. Specialy when one has a fluffy air-transparant feedstock such as blocks or chips.

It is dificult to predict the balance air from top/ air from nozle(s) over time and when this balance or unbalance eventualy disturbes the oxidation. People who have followed my tests know, that I myself tried to get more control over the process, by keeping a constant, and vast amount, of material above my oxidation (My so called “Material Lid”), Mukunde does more or less the same and has even for this purpose build a very high (2.5metres) and slender gasifier tower. He thus has A real masive material lid. It helps also that his fuel (rice peals) is very dense.

Appart from the “Material Lid” I experimented later with a ring cutted around my material tube. (The so called “Slit”). At this “Slit” I observed the kreeping-up came to a stand still.

With every adaption, my gas quality got better and better. It motivated me, to withstand the long nightly burn sessions, glaring for hours in the flare, untill my eyes acked. At last came a giant step forwards which made it even possible to me, to produce tarfree gas with a basic simple gasifier (The DriZzleR) together with a basic simple fuel feed technique (The DriZzling method). This technique made it easy and simply to fix the oxidation on spot. I discovered this technique after observing the nice blue flare from a dying out gasifier. When I finaly found a way to reproduce this phenomen of a starving gasifier, the DriZzleR was born. Somewhere july/august 2013 I described this invention, filmed it, and named it later “The DriZzling Method”.

This new concept does not only produces tarfree gas, but as prooved by Pascal (Crank) in his cogenerating setup, The DriZzleD gas is perfect engine grade gas.

Why is it that a “DriZzleR” produces engine grade gas and other open tops as FEMA are producing tar. Lets have a look at this drawing of a simplified DriZzleR.

- Schema of an OPEN-TOP Drizzler-Gasifier

Fundamental diference is; that the oxidationzone in a "DriZzleR" gasifier is not able to kreep up, This by the simple fact that in a "DriZzleR" there is no possibility to kreep up. Where the hopper or the fuel tube in a standard gasifier is kept full, (See a sketch of a stratified gasifier). Or where it is filled up by an auger in order “to feed it” and not to “starve it”, in a Drizzler the hopper is almost completely empty. (apart from a few hundreds gramm coal and the regular few hundred gram fuel to prevent it from burning out). The hopper in the DriZzleR is kept systematicaly at the lowest level. (This level can vary from fuelsort to fuelsort). The little bit material (red in the drawing) is part reduction,coalbed and oxidation, all in one. I call it the “Flaming Pyrolysebed”

Of course, By saying this I excagerated a bit, The layers drying, pyrolysing, oxidating, reducing still are existent but they are so close reacting, that the one can not destabilise the other.

Just an example. In a clasical closed imbert style gasifier, The oxidation (The little exstreme hot ball of fire around the nozle’s) has enormous much to empower. It must; dry and pyrolyse the full hopper of feedstock. At the same time it must bring, in water shift, the mass of falling off condenswater from the fuel without cooling too much down, keeping enough temperature to crack all the light and heavy volatiles and still be able to start the reduction. That is realy the reason why an Imbert is so hard to dimension, to fit nicely every process together.

In a DriZzleR the whole proces is supersimple. The oxidation, is in contrary to an Imbert Style, very dominant. Not a small ball of fire but a gigantic surface of oxidation to the relative small amount amound of fuel. (only a few hundred grams). The litlle bit of fuel gets dryed almost inmlediatly if not already partly by falling down in the hot fuel tube. It also gets almost inmediatly pyroliest and the little amount of nasty’s getz easely and without any stress handled by the dominant and big oxidation. Theroreticaly all the traditional layers are there but practicaly one can say ‘'”In the Flaming pyrolyses, they are all in one”.

As Stuart Perkins very understandable describes;

The concept is incredibly simple. By restricting the amount of fuel

being gasified to that which is in the immediate vicinity of the

pyrolysis zone, that is, no "full" hopper above, you eliminate the

excessive tars being produced. By keeping the tars being produced to an

absolute minimum, these tars are quite handily cracked by the pyrolysis

zone and voila...engine grade gas. Sometimes, the simplest solutions

evade us for years... We, people that is, are too smart to do the

simple things. Good job Luk, for being smart enough to try something

so obvious the rest of us missed it. ;o)

being gasified to that which is in the immediate vicinity of the

pyrolysis zone, that is, no "full" hopper above, you eliminate the

excessive tars being produced. By keeping the tars being produced to an

absolute minimum, these tars are quite handily cracked by the pyrolysis

zone and voila...engine grade gas. Sometimes, the simplest solutions

evade us for years... We, people that is, are too smart to do the

simple things. Good job Luk, for being smart enough to try something

so obvious the rest of us missed it. ;o)

Because the “pyrolyse/oxidation” or better called the “Flaming pyrolysebed” stays always fixed on the same level by a targeted and limited feed of fuel, there are no nozles needed for fixation of the oxidation zone. Also nozle’s are not needed for suply of oxigen to keep the oxidation going, because trough the open top, the Flaming pyrolysebed is richly flooded with air. One need no lid since there is no build up of gas in the hopper, therefor no puffs. There is no need for a preheating system, because the flaming pyrolysebed gives off so much heat, it inmediatly heats up the inflowing air. Also the fuel tube does not suffer from heat losses because it is vented around the “DriZzle tube” by the upwards streaming gas in the double mantle. No smoke too because the littel amount of fuel is on the spot transferred into coal. No fear for gaspoisining no CO. A "DriZzleR" can be operated fearly safe.

That does not mean that I will take any responcibility for accidents whatever. Gassing of wood is still a dangerous business. Do not even begin if you are not aware of that and if you are not sure of what you are doing.

”Th DriZzler Method" is “just in time" feeding of the gasifier that little amount that the gasifier is able to inmediatly process. That is the real secret. The method is more important than the gasifier design. Although this new method has led to a very simple gasifier ‘'”The DriZzleR” I am sure it can be aplied to almost any other gasifier design. You can use “The DriZzleR Method” in an Imbert, a GEK, a Victoria and also in a FEMA. And here I am back at the beginning of this article.

That does not mean that I will take any responcibility for accidents whatever. Gassing of wood is still a dangerous business. Do not even begin if you are not aware of that and if you are not sure of what you are doing.

”Th DriZzler Method" is “just in time" feeding of the gasifier that little amount that the gasifier is able to inmediatly process. That is the real secret. The method is more important than the gasifier design. Although this new method has led to a very simple gasifier ‘'”The DriZzleR” I am sure it can be aplied to almost any other gasifier design. You can use “The DriZzleR Method” in an Imbert, a GEK, a Victoria and also in a FEMA. And here I am back at the beginning of this article.

There is, as I am aware of, great resistance in the gasifier world to try “DriZzling”. It does away with all the cherished and pampered gasifiing dada’s. Such as nozle designs and openings, airpreheating, complicated formula’s for gasifier dimensions, etc. etc. Seeing that newer gasifier designs are even more going the sofiticated road, it is hard to believe that, one of the most simple gasifier ever build, is able to produce the same and even better quality engine grade gas as the superengineerd types.

See the sketch. It can not be more simple. Only a drum (the ashpit), a Pipe in the drum welded on the lid of the drum, (the DriZzling fuel in pipe), a plate with a hole and a tube under the hole,(the restriction and reduction) unlike Imbert nor very critical, and the length of the reduction pipe according to the wished temperature (The longer the pipe the cooler the exit gas) If too much gasspeed add eventual a bell. Finaly a grate. As said when one like to make a quick test open your imbert style, close the nozles and start DriZzling.

One important remark to people asking me for drawings. The “DriZzler” is for us, Pascal and me still a laboratory gasifier project and tests lead still to constant adaptions. But the adaptions are detail adaptions.

The most important in a “DriZzleR” is not the machine but the method.

This is maybe the little disadvantage of a “DriZzleR” One has to get the Knack. One has to get to feel how much or how little fuel one can suply. Best to practise while flaring. In the learnproces always keep an eye on the flare. First, when you burn the charcoal, apears a nice blue flare, later an ugly yellow red and when temperature comes up it gets violet and blue violet. Overall It can take a bit longer to get a flare. By big underpressure around and above 40milibar, with airtransparant fuel as chips beware that your reduction tube is not sucked empty.

As said above. Restriction is not critical. Pascal (Crank) connected on his same DriZzleR gasifier a 1.6liter VW car engine and later it worked fine, with the same setup, also with a small honda.

When you get the Knack by DriZzling, you can later easely automatises “DriZzling” with an augerfeeder based on time interval.

Beware. This is only the fact with generators connected and controlled by the grid and by small generators where the load is little. By isle operation with variable load on a bigger engine and generator, a level controler for the “Flaming Pyrolysebed” will be needed. Pascal right now is testing several options. Tom is testing with temperature changes.

So if you want to try. Much succes. Me and Pascal are ready to help.

Post here your experiences so we can all learn from it. More heads, more knowledge. And be fair. If you post or mention somewhere else your results give credit to the inventors, me and Pascal, and use the right terminology “DriZzleR”, “DriZzleR gasifier” and “DriZzing Method”.

Thank you all

Luk.

8. Februar 2014

Yesterday I made a few measurements of temperatures at my DriZzleR . Who will be surprised by low temperatures at the gas outlet now after this video understand what is happening through the "flaming pyrolysis". In the "flaming pyrolysis", temperatures up to 1300°C, more unfortunately, I can not measure it with my thermometer. Directly beneath the "flaming pyrolysis", the temperature drops dramatically. from 2cm below the zone there are only about 1000°C. by 10cm only 700-800°C.

Now you can see it is only a very small line where the complete reaction is going by. A small Line with about 3-4cm Where the complete Gasification Process will be end. Thats why you need to see the "Flaming Pyrolysis in your gasifier. If you put more fuel over it you can get Problems with the Temperature and also the Tar crackings (It depends also on your fuel /dry/wet...). I tried to add about 5cm Fuel (Pellets) over the "flaming pyrolysis" even then the maximum temperatures i get was about 1100°C. You see less is more in this System. To have tar free woodgas.

It should be noted that a reduction of 10cm below the flaming pyrolysis is not required. You will only need a good coal bed of 10cm length. With the among of 0,6l Charcoal in it. In my DriZzleR this coal bed is in a 10 cm wide and 10 cm long tube. After that there comes a 150cm pipe, 7cm long, where the gas can relax. Then comes the grate.

You can also run the DriZzleR completely without a grate only with a Plate. But you will get Problems if you connect an big engine or burning very fine fuels after a time of 2-3 hours gasification. You need a very slow rotating grate. if the Underpressure is going up over 10-20mBar then normal operation you have to shake very slow.

regards Pascal Kirchner

"the DriZzleR Gasifier"

---

Gestern habe ich einige Temperaturmessungen an meinem DriZzleR Vergaser gemacht. Wer erstaunt über niedrige Temperaturen am Gasausgang ist wird durch dieses Video verstehen warum es unter der "Flammenden Pyrolyse" kälter wird. In der "Flammenden Pyrolyse" steigen die Temperaturen über 1300°C. Mehr kann ich leider mit meinen Thermometern nicht messen. Direkt ca 2cm unter der "Flammenden Pyrolyse" sind nur noch 1000°C messbar. Danach gehen die Temperaturen drastisch zurück. Nach 10cm ist die Temperatur nur noch bei 700-800°C.

Nun kann man gut erkennen in welch kurzer Schicht die komplette Reaktion abläuft. Deshalb ist es auch wichtig die "Flammende Pyrolyse" im Vergaser zu sehen. Wenn man mehr Brennstoff über die "Flammende Pyrolyse" gibt, kann es Probleme mit der Temperatur geben. Sobald die Temperatur abfällt kann auch Teer nicht mehr richtig "gecrackt" werden (Abhängigkeiten vom Brennstoff wie Nass/trocken/...) Ich habe versucht ca 5cm Brennstoff (Pellets) über die "Flammende Pyrolyse" zu geben. Danach steigt die maximale Temperatur nur noch auf 1100°C. Man sieht also deutlich weniger ist in diesem System mehr. Wenn man Teerfreies Holzgas erzeugen will.

Auch merkt man, das eine Reduktion in 10cm Entfernung unter der Zone sinnlos ist. Man braucht nur ein Kohlebett von mindestens 10cm Länge. In meinem Fall sind das ca 0,6l Holzkohle. In meinem DriZzleR liegt diese Holzkohle in einem Rohr mit 10cm Durchmesser und 10cm Länge. Danach kommt ein 150cm Rohr, 7cm lang indem sich das Gas entspannen kann. Danach kommt der Rost.

Man kann den DriZzleR auch komplett ohne Rost betreiben nur mit einer einfachen Metalplatte. Aber nach einer Brenndauer von 2-3 Stunden mit einem großen Motor und kleinem Brennstoff kann es zu Problemen kommen. Man braucht einen sehr langsam laufenden Rost. Nur wenn der Unterdruck über 10-20mBar ansteigt muss vorsichtig der Rost gedreht werden.

viele Grüße Pascal Kirchner

"the DriZzleR Gasifier"

Abonnieren

Posts (Atom)